This is the continuation (page 3 of 3).

Table of contents

Startup

1. test

At the first startup I unfortunately noticed that the rotor did not begin to move by water or by compressed air. The reason for this were the four shaft sealings which friction was obviously much too high.

1. modification

To get the rotor moving, I had to disassemble the turbine almost completely so that I could remove the shaft sealings. Then I reassembled the turbine in the same way as on the first time.

In spite of the removed shaft seals, the turbine is still completely sealed, however, you can't fill oil into the turbine, which will shorten the lifetime of the bearings.

2. test

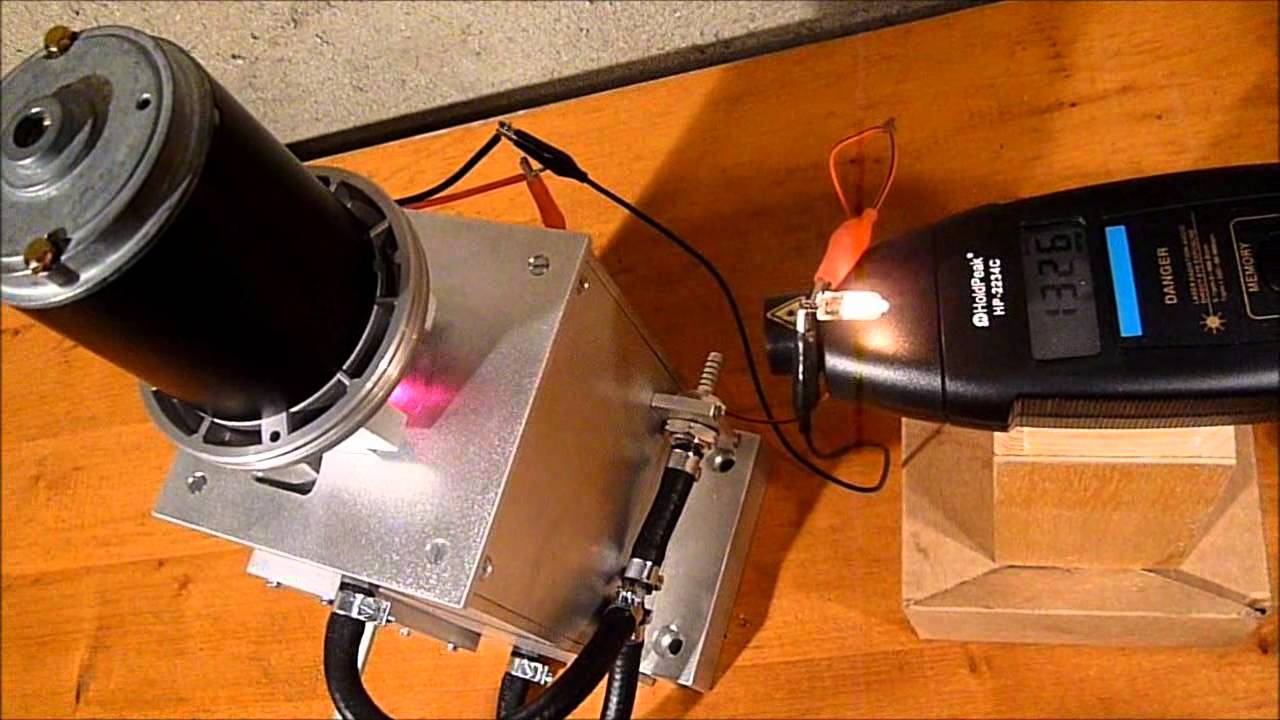

Video

The turbine worked, so I was able to run functional tests.

First, the turbine was tested with compressed air (about 8 bar). For this I kept the blow-out nozzle as close as possible to the discs.

Measurements / calculations

The following values were measured:

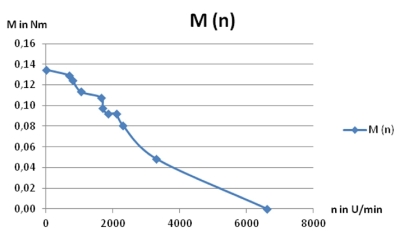

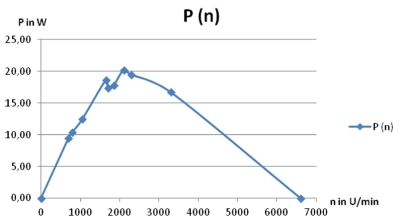

Torque depending on the rotational speed:

Power depending on the rotational speed:

I couldn't measure the input power and therefore I don't know the efficiency.

3. test

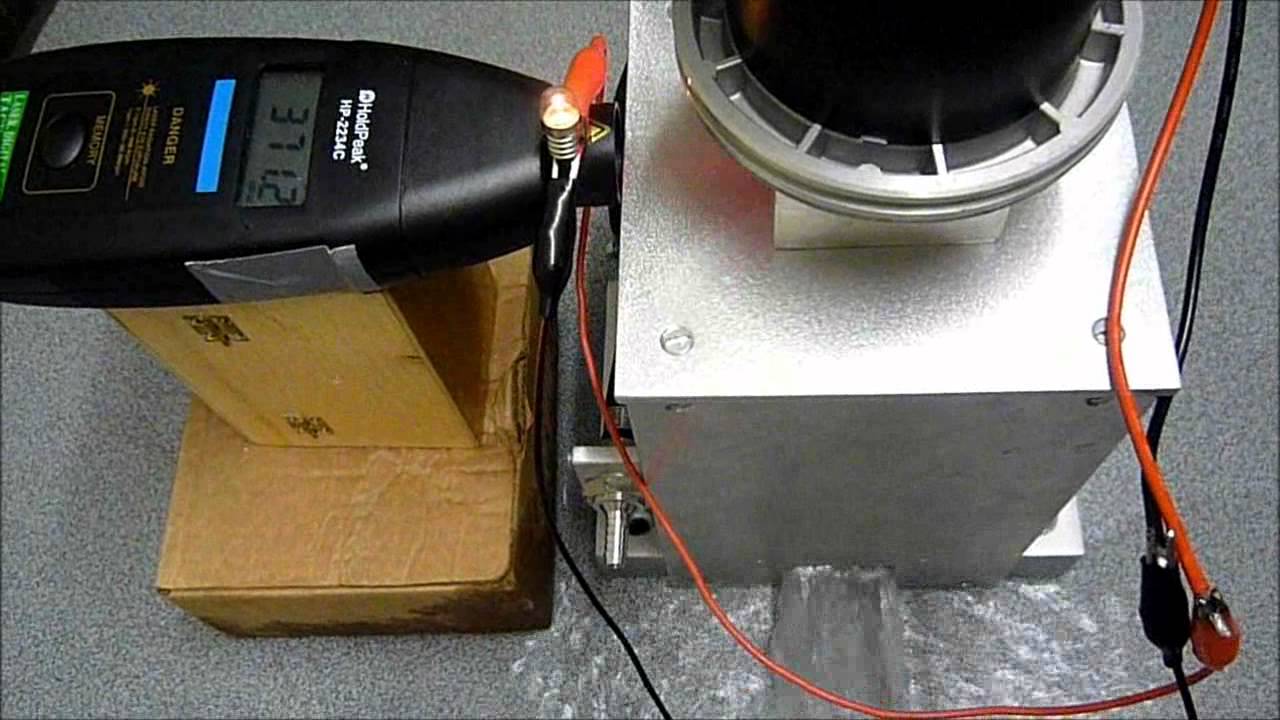

Video

The following video shows the Tesla turbine in operation with water (pressure = 1.1 bar, flow rate = 0.37 l/s):

Measurements / calculations

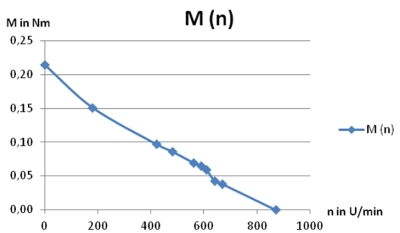

Torque depending on the rotational speed:

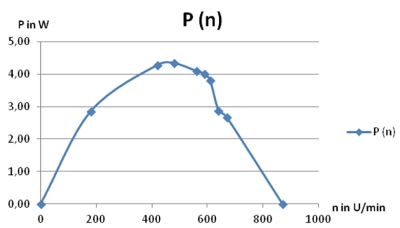

Power depending on the rotational speed:

The calculated efficiency was approximately 4.3%.

4. test

Measurements / calculations

This test was the same as before, just with a slightly higher inlet pressure (1.5 bar). The flow rate was about 0.41 l/s.

Torque depending on the rotational speed:

Power depending on the rotational speed:

The calculated efficiency was approximately 7.1%.